Wax setting casting technology for jewelry is a new technology that emerged in the mid-1990s. Once this technology appeared, it attracted wide attention and rapid promotion in the jewelry-making industry, especially in making jewelry pieces with many inlaid stones; the wax setting process has become a meaningful way to reduce production costs, improve production efficiency and increase product competitiveness. The so-called wax setting is relative to the gold setting; it is pre-set in the wax model before casting; after preparing the plaster type, dewaxing, and roasting, the stone is fixed in the plaster wall of the cavity; when the metal liquid is poured into the cavity, the metal liquid wraps the stone, and after cooling and shrinking, the stone will be firmly fixed in the metal setting mouth. The wax setting technology is based on the traditional investment casting process. However, it has unique features and difficulties in each production process, bringing certain risks to jewelry processing enterprises. Only with a complete understanding and knowledge of the wax setting process and strict operation according to the requirements can we ensure the stability of the wax setting quality and give full play to the advantages of the wax casting process.

2. Rubber mold and wax mold making

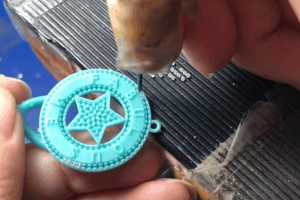

3. Gemstone set into wax mold

4. Planting wax trees

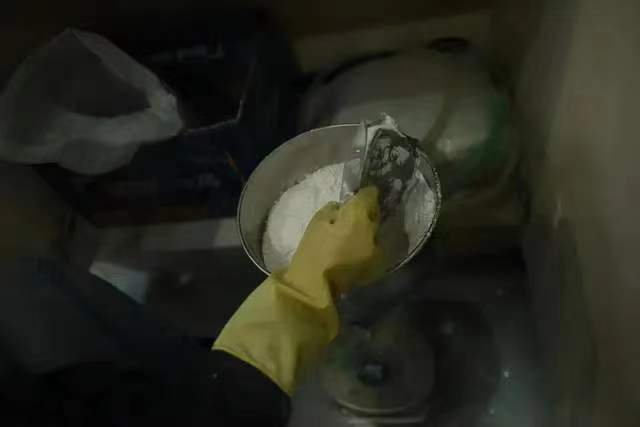

5. Plaster type production

6.Gypsum-based dewaxing and roasting

7. Metal roasting and pouring

8. Trim cooling and cleaning

Advantages of the wax casting process.

①Save time and improve production efficiency. As the time required jewelry factory for wax setting, the same number of stones is much less than the gold setting, thus significantly enhancing the efficiency of production; the labor intensity of the wax setting is also much less than that of the gold setting.

②Reduced labor cost. The traditional gold setting operation has relatively high requirements for the operation skills of stone setting workers, making jewelry factories in the stone setting sector invest a large number of skilled workers, significantly increasing labor costs, especially for low-value jewelry pieces, the proportion of labor costs in the total cost is very high, and the use of the wax setting process, can significantly reduce labor costs and improve the competitiveness of the product market.

③Reduced metal loss. In the wax casting process, the stones are set into the wax mold before casting, so there is no need to polish the mouth of the setting, as in the traditional gold setting process, which means less metal loss. In the case of wax settings, the wax mold is trimmed, so the metal loss is significantly reduced. It also eliminates the need to collect and purify the gold powder waste.

④Reduced the cost of using tools. The traditional gold inlay process requires a series of inlay tools, such as cranes, machine needles, oil stones, and various hand tools. On the other hand, a wax inlay requires only simple tools, thus reducing the cost of using and losing polishing tools such as machine needles and motor cranes.

⑤It is beneficial to realize the innovation of jewelry design. Some jewelry design styles and structures are difficult to make with the traditional gold setting process. However, they can be recognized with the wax setting process.

Disadvantages of the wax casting process.

①In the technique of wax setting casting, there is a risk of fragmentation and discoloration due to the high-temperature roasting of the stones and the thermal impact of the high-temperature metal fluid during pouring.

②In the roasting process, to reduce the probability of problems with the rocks, the roasting temperature of the gypsum is lowered, making it possible for residual carbon to appear in the casting, making the alloy more susceptible to contamination than conventional casting and increasing the likelihood of porosity and sand holes in the casting.

We will contact you within 1 working day, please pay attention to the email with the chris@alimajewelry.com